To transform a rotational movement into linear movement with high forces mostly spindles or racks are used.

For screw jacks the pitch and the number of threads are the main variables and for racks it is the modulus and the pinion's tooth number.

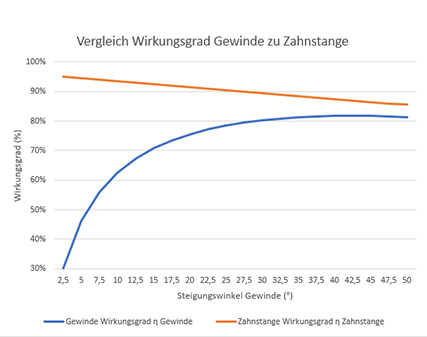

Due to „Niemann“: η=tanα/tan(α+ς) screw jacks have bad efficiency because of the sliding between nut and spindle.

Causal for this is the high sliding ratio in the movement (cf. Niemann: „Maschinenelemente“ Band 1, Springer Verlag, 2. edition 1981, p. 203).

With toothed gears the revolving movement, the rollover, outweighs the sliding. The efficiency ratio is, conferred to „Linke“, definded over

the loss ratio of the cogging:

cogging loss = friction coefficient * cogging loss factor =

Vz = µ * Hv. tooth efficiency = ηz = 1 – Vz (cf. Linke: „Stirnradverzahnung“ Hanser

Verlag, 2. edition, 2010, pp. 387).

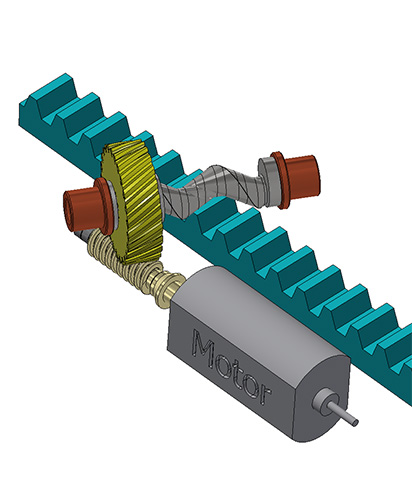

Evoloid racks

The diagram shows the better efficiency ratio of racks compared to screw jacks.

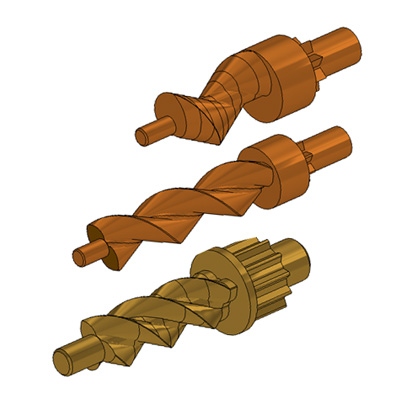

Evoloid gears are gears in which at least one cog wheel has a number of teeth

less than 5. Since 1965 those are known in spur gears with parallel axes.

Gears with a number of teeth n=1, n=2 and n=3 have special advantages.

We are able to design and deliver evoloid racks with a pinion with small number of teeth.

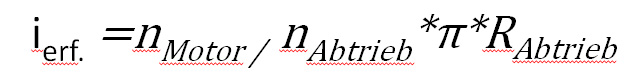

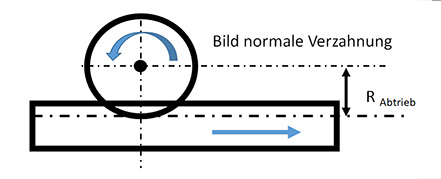

The higher the radius on the input wheel, the higher is the output revolutional speed and therefore the needed transmission ratio of the whole gear.

The higher the radius on the input wheel, the higher is the output revolutional speed and therefore the needed transmission ratio of the whole gear.

The smaller the radius of the input wheel, the smaller is the needed output torque of the whole gear.

The smaller the radius of the input wheel, the smaller is the needed output torque of the whole gear.

Evoloid rack pinion with teeth number 1, 2 and 3

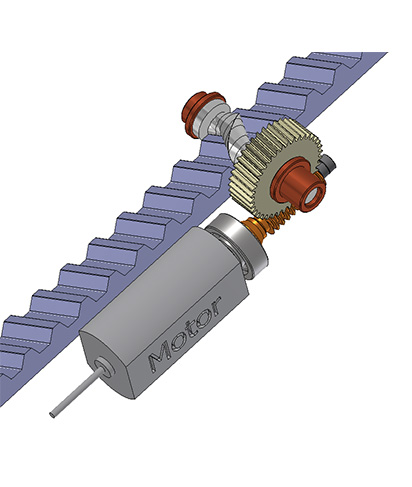

Evoloid rack pinion with tooth number n=1 and worm gear with transmission ratio i=75:1

Cost efficiency example

Gears to create a high force and slow movement:Calculation example reduction ratio A calculation example shows the advantages on a commonly used actuator with an input speed of 5000 min-1 and an output speed of 9 mm/sec = 540 mm/min.-1 A gear with pinion's teeth number n = 15 and modulus M = 1 mm has a perimeter of 15 teeth *π* Modul 1 mm = 47,12 mm; therefore the output speed is 5000/min *47,12 mm = 235619,45 mm/min; reduction of i= 235619 mm/min/540 mm/min = 436:1;

Therefore a gear with several stages is needed A pinion with teeth number n = 1 and a Modulus of 2 mm has a perimeter of 1 * π* 2 mm = 6,28 mm and therefore the needed reduction is only 5000/min * 6,28 mm / 540 mm/min = 58:1 It is only needed a one-staged gear with for instance a worm gear or an evoloid gear.

This calculation example shows the possible savings by reducing parts and therefore costs.

Cost example:

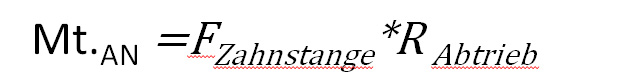

Gear to create a high force an slow movement:Calculation example output torque and rack force: The pinion above with number of teeth n = 15 and Modulus M = 1 mm has a lever arm of 15 * 1 mm/2 = 7,5 mm. So the needed torque is 500 N * 7,5 mm = 3,75 Nm. A pinion with teeth number n = 1 and Modulus M = 2 mm has a lever arm of 1 * 2 mm/2 = 1 mm. The needed torque here is 500 N * 1 mm = 0,5 Nm.

The example was built with similar parameters. The gear with a 24 V DC-Motor with ~1 A motor current and 30 mNm torque at a speed of 5000/min and a tooth force of 500 N has an output speed of 9 mm/sec. The noise emission is very low. By reducing the needed quantity of stages and parts and reducing the motor power the costs can be lowered. Less stages also mean less friction contacts, so the efficiency ratio is higher and energy can be saved.

About the backlash

Due to the reduced number of stages, in extreme cases down to only one stage, the number of needed toothings for the transmission is also decreased. If only one stage is needed there is only one possible contact point creating the backlash. So the backlash can be reduced to a few µm. We built gears with a total torsion angle of several arc seconds, so that the whole gear torsion angle was around 5 arc seconds.We already built several evoloid gears and some of our designs are used for large-lot production. The shown gears have been built and the gear characteristics have been experimentally proofed.

The evoloid rack gears with pinions with teeth number n=1, n=2 and n=3 are filed as patents in many one- and more-staged gear combinations.

Do you have any further questions or need more information?

You can contact us via our contact page.

Phone 0049 2405 408 1650.

Technical report (PDF-file)

If you are interested we will send you the required technical report as a PDF document. Please use this to request our Contact site.