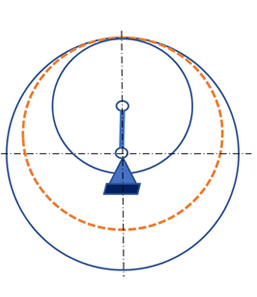

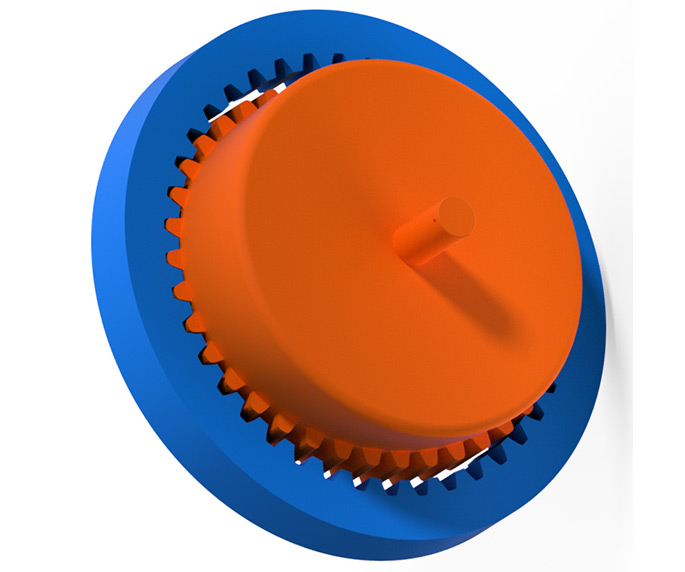

Strain wave gear created by an eccentric disk

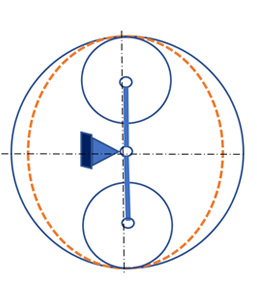

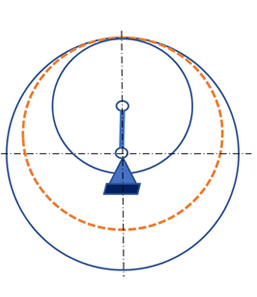

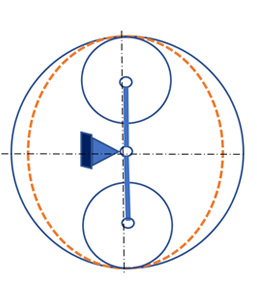

Strain wave gear created by two disks

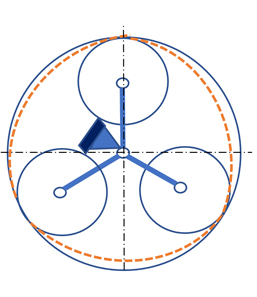

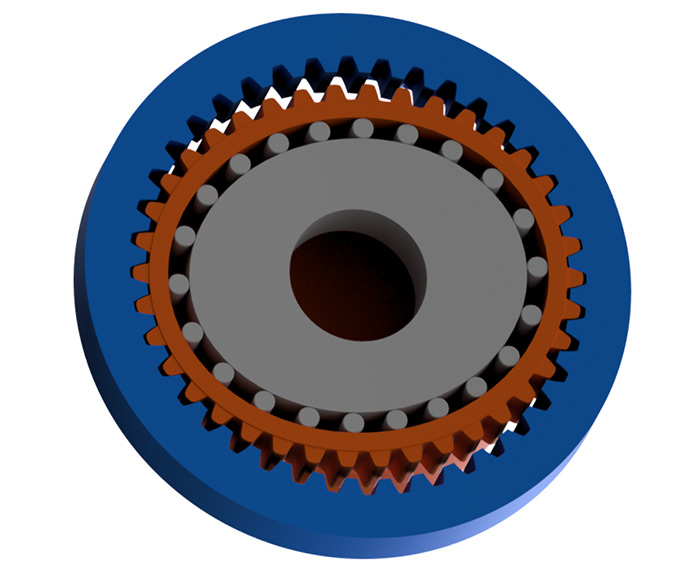

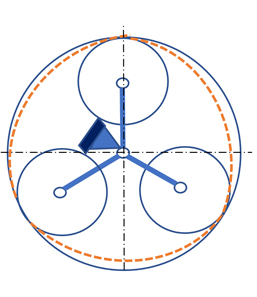

Strain wave gears are epicyclic gears with an elastically deformable gear ring. With only one gear stage high reduction ratios can be accomplished. They can be designed with inner and outer toothing. Most commonly, a dual polygon is used as an inner oval, but other polygons are to be designed. However, the former has enforced due to its advantageous static behaviour and the compensation of imbalance. Only short toothing can be used, because

just then the deformation of the gear ring is controllable. The contact area of bearing teeth is computed to approximately 15%. If the inner oval is constucted springily, the rotation is transmitted almost with zero backlash. There is an increasement of friction loss, though. In stead of an inner oval, several rolls can be used. Excecution in steel, plastic and a combination of both materials are possible. We can design and produce such strain wave gears.

You can contact us via our contact page.

Phone 0049 2405 408 1650.

If you are interested we will send you the required technical report as a PDF document. Please use this to request our Contact site.