Problem solving by means of the example of a 90° elbow connector: if the mechanical system is chosen so that the direction of movement is vertically during the clamping process, a profile shift is impossible.

Problem solving by means of the example of a 90° elbow connector: if the mechanical system is chosen so that the direction of movement is vertically during the clamping process, a profile shift is impossible.

A double wedge is most qualified for this purpose. If the position of the profile’s components are opposite each other, a shifting during the clamping process cannot happen.

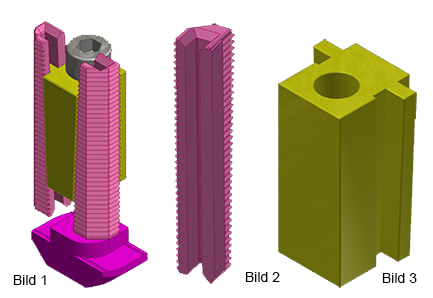

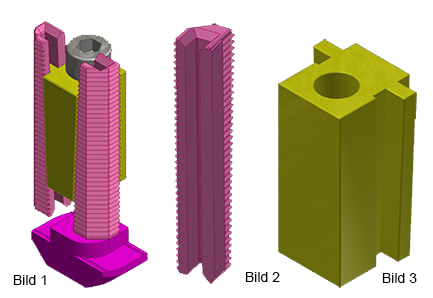

Image 1 (Bild 1) shows a profile elbow connector that was designed after these principles. It consists of the following four components: cylinder head screw, two side wedges (mirror-imaged, image 2/Bild 2) and one double wedge (image 3/Bild 3). To create a clamping force, a DIN 912 screw is used.

Assembly process: a slot nut with a thread hole is placed into the cross section. After the profiles have been positioned towards each other, the lateral wedges can be inserted into the vertical profile. Now, the double wedge can be inserted into the profile slot together with the cylinder screw and be shifted between the side wedges. The system immediately jams and without a positional shift, due to the impact of the flat fivefold wedges. If the screw is put in the t-slot of the cross profile, the wedges become wedged in the profile, which causes a very solid fixture. In doing so, the vertical profil is pressed onto the cross section. As The wrench (electric screwdriver) a normal kardan wrench is usually used for both the rough turning and for the turning afterwards. Because of the self-retaining fivefold wedges, and the resulting reduction, a strong tightening is not necessary.

We are glad to help you. Feel free to contact us

via e-mail or phone 0049 2405 408 1650.

This product has been patented.