We design gears particularly for stepped up trasnmission. The toothing is specifically designed to place the area of operation behind the point of contact in order to achieve sliding friction. Depending on design, gears with high reductions can easily be produced with a ratio ranging from i = 1 : 1 to i = 1 : 200 or even significantly higher.

Stepped up transmission

Both, outer and inner toothing can be accomplished. In some extreme cases, the advanced design does not tolerate small defects. The gear box may be blocked.

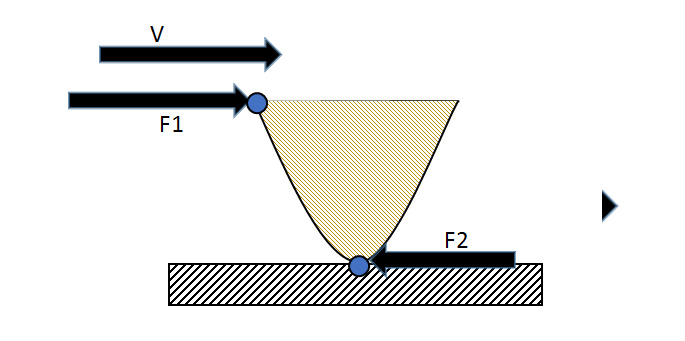

Rattling braking friction

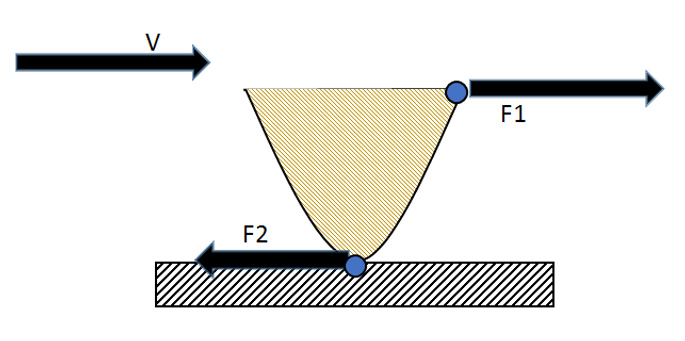

Sliding and detaching friction

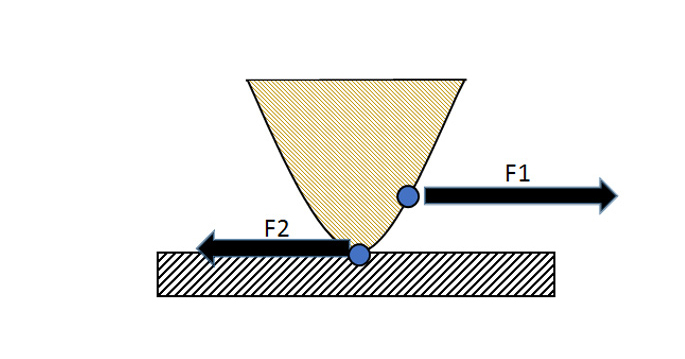

Sliding friction

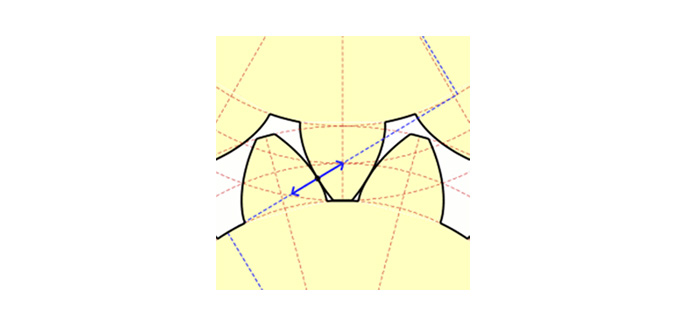

Usally, the area of action is behind the point of contact to a great extend for involute toothing (picture by Claudio Rocchini).

Examplary planetary drive, ratio i = 10 : 1

Do you have any further questions or need more information?

You can contact us via our contact page.

Phone 0049 2405 408 1650.

Technical report (PDF-file)

If you are interested we will send you the required technical report as a PDF document. Please use this to request our Contact site.