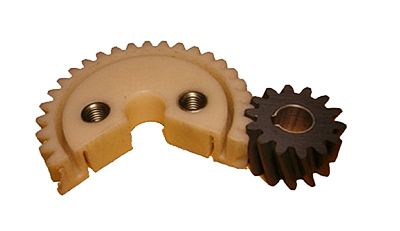

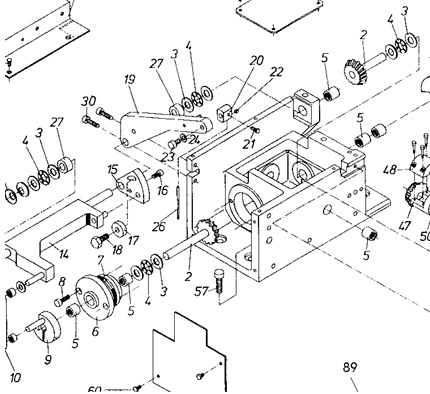

Toothing calculation and gearbox design

If a toothing design is not yet fixed by the customer we define first which kind of toothing fits the best to fulfill all requirements. We know many variants of design and there is almost none which we did not use for our customers: spur gears, crown gears, worm gears, screw wheels, bevel gears, beveloid wheels or cycloidical toothing we design with the software KISSsoft. As a specialist for evoloid gears we are also able to design most of these various types with few teeth on one wheel.During the design phase there are also many more variables than the type of toothing or the number of teeth: an easy spur gear pair for example can also be designed for good acoustic behaviour, high efficiency rate,cheap mass production, a low rate of reverse backlash or other aims of optimization.