Planetary gears have many advantages to other gears:

1. Compact built and highly stressable.

2. Simultanously load distribution to many teeth.

3. High transmission ratio in one stage.

4. Combination of several stages by shifting behind each other.

Planetary gears with three planets have even more advantages:

I. Good load distribution up to 2x3 = 6 teeth (in helical toothing).

II. Symmetrical force polygons as an equilateral triangle.

III. Centering of the sun wheel and the hollow wheel by planetary forces

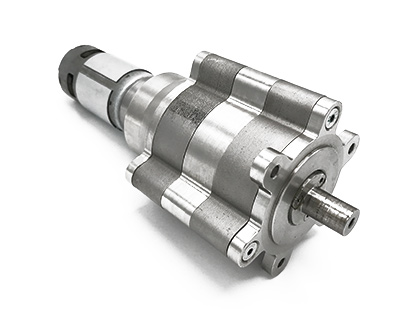

Advantages of planetary evoloid gears

Therefore planetary gears are preferably built with three planets.

In planetary gears with three planets one problem exists quite often: for higher ratio the sun wheel needs to be small and the planets need to enlarge. At a ratio of around 12:1 the planets collide with each other.

We achieved planetary gears with ratios from (i=6:1); i=12:1; i=18:1; i=24:1 i=30:1; i=36:1; i=42:1 which all have three planets in one stage. By choosing the fitting toothing geometry those gears can base

backdriveable up to high ratios.

Planetary gearbox type series with three planets and a sun wheel consisting of one tooth:

Planetary evoloid gears with a one-toothed sun wheel have many advantages to for instance planetary gears with two stages:

1. Higher efficiency due to less friction wear points compared to gears with more stages.

2. By increasing the modulus the load capacity of the gear is higher.

3. Evoloid gears are more cost efficient due to less produced parts.

4. The emitting noise can be reduced up to 10 dB(A).

5. The installation space can be decreased.

i=12:1

S=1, P=5, H=11

one stage: i=12:1

two stages: i=144:1

three stages: i=1728:1

i=18:1

S=1, P=8, H=17

one stage: i=18:1

two stages: i=324:1

three stages: i=5832:1

i=24:1

S=1, P=11, H=23

one stage: i=24:1

two stages: i=576:1

three stages: i=13824:1

i=30:1

S=1, P=14, H=29

one stage: i=30:1

two stages: i=900:1

three stages: i=27000:1

i=36:1

S=1, P=17, H=35

one stage: i=36:1

two stages: i=1296:1

three stages: i=46656:1

i=42:1

S=1, P=20, H=41

one stage: i=42:1

two stages: i=1764:1

three stages: i=74088:1

Any questions or need more information?

You can contact us via our contact page.

Phone 0049 2405 408 1650.

Applied for patent

This product has been patented.